Mount Holyoke fosters maker culture in new facility primed for curiosity

On a sunny afternoon in April, the ground floor of Prospect Hall is alive with activity. In the light streaming through floor-to-ceiling windows that look out on Lower Lake, several students are assembling a cardboard model of a wooden desk where a student worker will greet visitors to the lab. Built of reclaimed materials, the piece will stand in the space long after its creators have graduated, and they plan to add their signatures to it, making it a legacy project for their class. Noticing a new face in the room, Makerspace Consultant Miranda Schmidt ’19 steps away from the group and approaches the visitor with a smile: “Welcome to the Fimbel Lab!”

Even with such a friendly reception, it can take a few minutes for the scope of the transformation to sink in. The makerspace’s move this year from its former quarters of less than 1,000 square feet in Art 211 to its new home of more than 8,000 square feet in Prospect Hall created room for an astonishing array of neatly marshalled tools and machinery. In addition to the laser cutter, vacuum former, two 3D printers, sewing machines, soldering tools and computers that the former space held, users of the Fimbel Maker & Innovation Lab — named for benefactor Nancie L. Fimbel ’68, who donated $1 million to support its creation — now have at their disposal a fully appointed (and skylighted) wood and metal shop; a computer-operated CNC milling machine; a second laser cutter; five additional 3D printers; and a water-jet cutter that can slice through stone. Hand tools of all descriptions are available. A fume hood and spray booth ensure the rapid removal of noxious vapors when students are varnishing or spray-painting their work. On the other side of the large windows is an outdoor space that has been discussed as a possible site for teaching and learning about auto mechanics. With five large work rooms and many more work spaces, numerous independent projects can progress even as classes are conducted.

Students work together on a lightboard designed and assembled as part of a class project.

Exciting synergies

“The phrase that I often use when discussing the Fimbel Lab is ‘cross-pollination,’” says Technical Lead and Design Mentor Kris Camp, who was hired in November 2018 as part of the makerspace’s expansion and move to its newly renovated location. “Because I see the space as a place where a diverse set of users come together to implement, adapt and expand concepts of creation that are often as diverse as the subject matter that each of us brings to the space. I see the lab as a space where people and ideas come together to intermingle and become greater than the sum of all their parts.”

In the general workshop, the muted whine of the CNC mill in the wood and metal shop can be heard through noise-reducing walls and windows, accompanied by the whoosh of the state-of-the-art dust collection system. While some students continue work on massing the desk in the lounge or “touchdown space,” others mill chair parts under Camp’s watchful guidance. Two students sit together in the large multipurpose room, watching a video on a laptop. Their presence confirms that in the months since the move, the Fimbel Lab has begun to fully realize the purpose for which it was created.

“The fact that it’s not part of an academic building is significant,” says Director of the Fimbel Lab and Professor of Physics Katherine Aidala, who serves as faculty lead for the makerspace. “This is a space owned by everyone at the College, and everybody is welcome. The idea that students can just drop in and hang out is critical to the feel and the friendliness and the welcoming nature of the space.”

Kinesthetic learning

A student presents a proposal for the desk project in Professor Naomi Darling’s design-build course.

Academic classes and projects still take priority. But one advantage of the new space, Aidala says, is that diverse maker projects can now happen simultaneously. Following the Lab’s soft launch in January 2019, numerous independent and student directed projects have comfortably coexisted alongside the desk- and chair-making happening in Naomi Darling’s design-build course as well as the activity generated by four additional academic courses that met regularly in the Fimbel Lab during the spring semester. Darling, a practicing architect and Five College assistant professor of sustainable architecture, says the kind of hands-on work students do in the Lab is essential to learning design competency.

“A big part of knowing how to design things is knowing how they actually get built,” she says. “It’s really important for students to go through the experience of designing, and then doing the drawings that communicate that design, and then actually building it. Once you know how materials come together, the lines that are really abstractions of a process become a lot more real.”

Aidala agrees. “Getting the feel of what it’s like to push a drill bit through the material is actually important to be able to fully use the computer-controlled technology in the metal and wood shop,” she says. “You can’t get that feel when you’re using the laser.”

Both Darling and Aidala note that the challenges students wrestle with in the Fimbel Lab serve not only as effective technical training but also as opportunities to learn confidence and gain a broader skill set.

People find it really empowering to translate an idea into physical form,” Darling says. “It’s a different way of learning and thinking than reading or writing an essay or doing a problem set.”

Life lessons

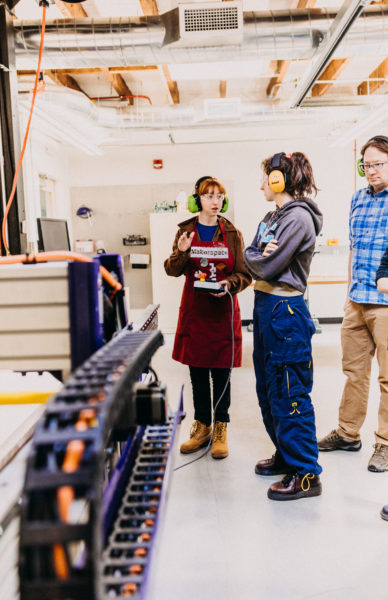

Miranda Schmidt ’19 (left), a student in Naomi Darling’s Topics in Architectural Studies class, talks with teaching assistant Monika Sharma ’19.

The Fundamentals of Maker Culture class that Aidala teaches with Shani Mensing ’15, the Fimbel Lab’s technical specialist, in which students learn to safely operate tools and machines and to develop and mentor projects, began as a practical course in using the lab and helping others to do so. The course still provides that training, but it also offers students a chance to gain self-awareness by reflecting on how they learn and communicate.

“It’s an opportunity to teach students not just about what kind of equipment is in the space but about the culture behind making,” Mensing says. “What does it mean to make in this space? What does it mean to be a mentor in this space? We dive into how to deal with difficult moments, the emotional intelligence necessary for problemsolving and how to figure out their own learning styles. The class originated as a way to get students trained for the space, but then we realized we could turn it into an opportunity to learn about what it means to be a mentor in general, and how students can apply those situations to everyday life.”

“Making embodies the liberal arts,” Aidala says. “It’s a unique form of learning, of knowing, of experiencing the world. It’s something that starts tying into ideas in entrepreneurship, ideas of project-based learning, where there’s something pretty unique about making a tangible object where there is no ‘undo’ option – if you make a mistake, you have to pivot or start from scratch again. It encourages risk-taking, and builds resilience, and it’s something where the idea of failure is flipped. It’s this idea that of course you’re going to make mistakes and of course things don’t work on the first try, so just keep trying and keep learning and keep iterating. And these are values of the liberal arts: critical thinking, analysis and problem-solving are explicitly goals that we work on throughout the curriculum. It also provides opportunities to apply tools to problems that you deeply care about, whether it’s social justice, environmental sustainability or something else.”

Conscious constructions

The reception desk was built from repurposed campus materials and includes student names imprinted into its front.

In keeping with those ideals, students using the space are encouraged to consider the impact of their creations. The working surface of the greeter desk from Darling’s design-build class – which was completed in May – is fashioned from the wood of the oak tree that was felled to make room for the Blanchard extension. Historic floorboards that had been in storage in facilities for nearly 100 years compose the desk’s body, while former window handles have been repurposed as drawer pulls.

“The Fimbel Lab helps students think about the materiality of the world we live in,” Aidala says. “We train students to consider efficient use of materials to generate less waste, along with reuse and recycling. We see the interests of our students come through in the projects, whether it’s developing a solar lantern for afterdark schoolwork in remote villages or researching alternative natural materials for textiles that could have the same physical properties as the synthetically derived textiles popular for clothing.”

While data on the number and frequency of users in the space is still being collected, Mensing, whose office is on-site, says she has seen a surge in interest since the move – which was itself promoted by the impossibility of fitting the creative impulses stirring on campus within the confines of one classroom.

The reception desk designed and built by students (pictured left with Professor Naomi Darling, front right) in the design-build class held in the Fimbel Lab.

“It brought a lot of energy to the Art Building,” Aidala says, “And it was clearly beneficial to many of those involved, but even from the outset, because we were in a digital media lab that was fundamentally a computational facility, we couldn’t really make dust, and it wasn’t designed as a lab facility where we had easy dust collection and ventilation for more complicated equipment.”

In light of the overwhelming success of the space in Art 211, and bolstered by the Fimbel gift and other funding, the College invested $3.5 million in a renovation of Prospect Hall. That amount allowed for the renovation and development of multiple spaces, as well as the ability to break a logjam around the high-tech cutting and prototyping machines, which had quickly grown popular.

“The ability to have a second laser cutter was huge,” Mensing adds. “When we were in Art 211 and we got the first one up and running, it was like a wildfire. But it was constantly in demand, so much so that we weren’t able to always meet the demand, and it put a lot of strain on the space to try to manage that. The ability to have a second laser cutter allowed for things to run a lot more smoothly, and we were able to get additional 3D printers in the space as well, which also helped. Now we’re able to meet the needs of the campus.”

The fervor around making shows no signs of subsiding, and the list of independent student projects keeps growing. Examples from the astonishing array of ideas being pursued in the Fimbel Lab include printed plastic splints to treat injured geese; jeans designed specifically for trans men; and topographic 3D models illustrating the discrepancies between student and faculty understanding of the vocabulary contained in a scene from “Hamlet.”

“The Chemistry of Pasta”

Madison Walters ’19 (left) and Miranda Schmidt ’19 were two of the students enrolled in classes held in the new Fimbel Lab this spring

Some of the projects are even edible. Madison Walters ’19 found a way to turn a personal passion into a fun and educational experience to share with other students. The child of a chef, and a student consultant in the Fimbel Lab, the architectural studies major and music minor saw big potential in the Lab’s kitchen, which was renovated when dining services operations that had been housed in Prospect and other locations on campus were centralized in the Community Center.

“While I was growing up, my mom was going to culinary school,” Walters says, “so I’ve always been super involved in cooking at a very fine level. My friends and I cook all the time at home. It’s something that I really connect with, and it surprised me to learn that not a lot of people are comfortable cooking in the kitchen.”

That realization sparked an idea: Why not invite others into the Lab to gain familiarity with culinary techniques while also learning a few principles of chemistry and physics and having fun at the same time? Walters had seen the enthusiasm around Chocolate Lab, a recurring event where students use the 3D printer and vacuum former to create delicious, customized gifts and treats while learning about the science behind the tempering of chocolate.

“It’s a really fun and engaging way to get people into the space,” Walters says, “because you’re motivated by the food aspect, but you also learn some science and you learn about a ton of the different technologies. So I was really hoping to do something similar to that.”

Working with Associate Professor of Chemistry Kathryn A. McMenimen ’03 in a 300-level chemistry independent study, Walters spent the spring semester learning about food science and gluten formation and developing a single-session class, The Chemistry of Pasta, in which students can gain skills in the kitchen, learn how to make food on a budget and explore the science behind how pasta is made and why it tastes the way it does.

“Our student staff gets together every other Saturday or so for a staff night where we’ll hang out in the space, play video games or go out on a field trip or something,” Walters says. “It’s a way for us to bond as a community. We’ll also use that time to learn new skills or to do some training in the woodshop. I asked Shani if we could set aside a staff night to do test my workshop before I did it with students, and she said, ‘Absolutely! Let’s do it!’”

For Walters, who is considering pursuing a graduate degree in historic preservation, the Fimbel Lab embodies some of the best aspects of their undergraduate experience.

“I worked in the admission office,” Walters says, “and I often talked to prospective students about the Fimbel Lab as a microcosm of what makes Mount Holyoke a really special place. It’s a very intersectional space, and I think Mount Holyoke as a liberal arts college really understands diversity and intersectionality on a different level. We can have a student in here hand-carving something out of wood in the woodshop, or laser-cutting a button for a friend, or painting a little psych-up picture for their teammate, or 3D-printing a splint for a goose. There are so many different levels of projects and community engagement happening here at any given time. And I think that that’s really unique to this space – and I think really unique to Mount Holyoke: Our students can find their own kind of crazy, interesting passion and then, with the resources here, take it even further.”

—By Abe Loomis

—Photographs by Joanna Chattman

Abe Loomis is a freelance writer based in western Massachusetts. Contact him at abe.loomis@gmail.com.

This article appeared as “Powering Up” in the summer 2019 issue of the Alumnae Quarterly.

July 29, 2019

This makerspace is the one thing on campus that I wish, more than anything else, had been there when I was a student.

This addition to the college appears to add many layers of value and potential. What a unique space for the students and faculty to enjoy! Wonderful work!